LDEC

3.0ml Ready-to-Use (RTU) Cartridge Assembly with Short Stopper-1 Tub - 100 pcs, 1500pcs/Case

3.0ml Ready-to-Use (RTU) Cartridge Assembly with Short Stopper-1 Tub - 100 pcs, 1500pcs/Case

Couldn't load pickup availability

Key Product Highlights

- Designed for Biologics: Purpose-built for peptide and protein injectable therapies, compliant with international pen‑style delivery standards.

- Premium Glass Material: Manufactured from clear Type I borosilicate glass with high hydrolytic resistance to ensure drug stability.

- Precision & Safety: Tight dimensional tolerances deliver accurate dosing while minimizing extractables, leachables, and breakage risk.

- Protective Nested Format: Cartridges remain nested during fill‑finish, preventing glass‑to‑glass contact and reducing particle generation.

- Complete Sterilization: Subjected to a six‑hour steam autoclave cycle, ensuring thorough sterilization beyond gas‑based methods.

- Production Compatibility: Standardized tub dimensions allow seamless integration into existing fill‑finish lines without change parts.

Key Features

-

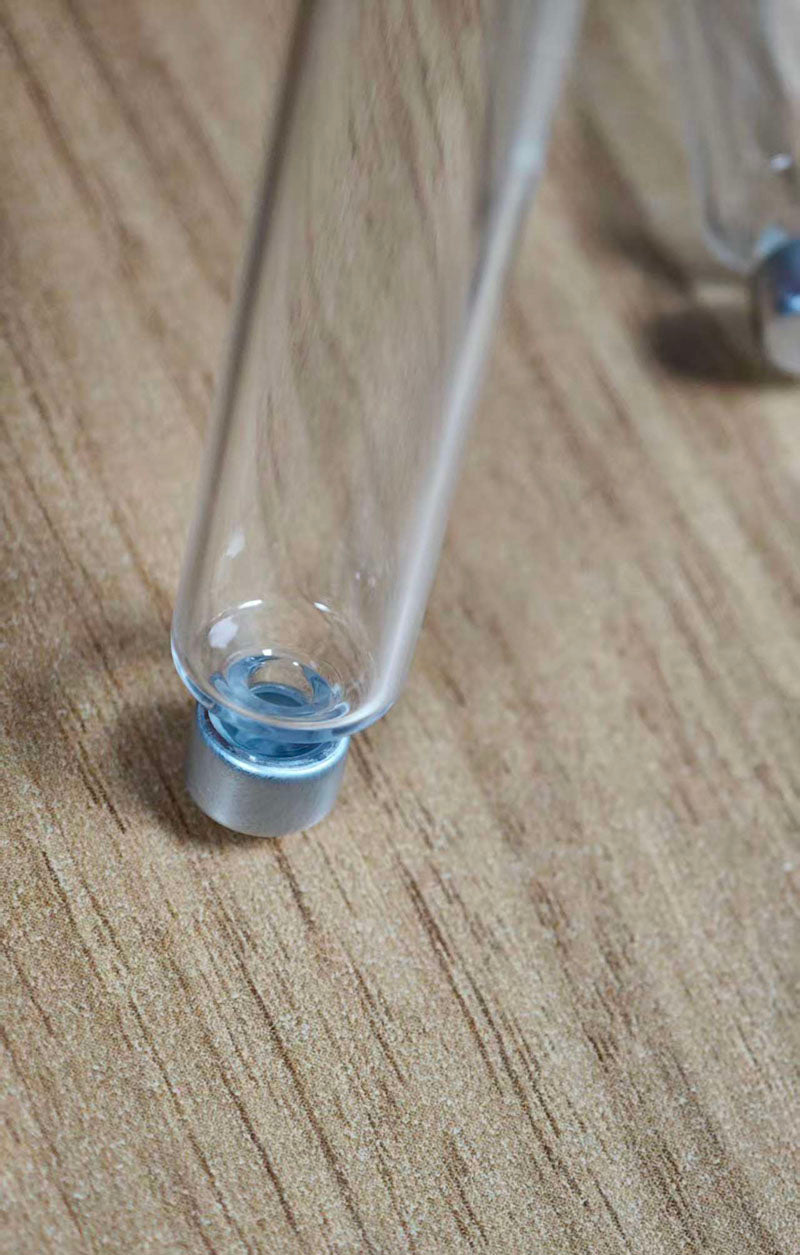

Cartridge Specifications: Volume: 3.0ml, OD: 11.6mm, H: 64.1mm

-

100 tub of 100 cartridges, 15 tubs per case

-

Package Weight: 12.80kg/case

-

Package Dimensions: 245mm x 450mm x 785

-

For use with insulin injection pens

Product Details

-

ISO 15378 and ISO 9001, 3mL cartridges

-

Steam sterilized (SAL = 10-6), Ready-to-use

-

Tyvek 1073-B Steam Permeable Autoclave Bag packaging

-

Cartridge body is made using Schott Pharma Type I Borosilicate Glass

-

Cartridge cap is Aluminum Crimp

-

Dual layer septa is Polyisoprene, Bromobutyl Rubber

-

Stopper is Bromobutyl Rubber 8.2mm "short style"

-

Rubber stopper is made of Butyl Bromide

Quality Details

-

Biocompatibility Test - ,Sterility, Bacterial endotoxin Comply NMPA-YBB QYC-T-CP-YGF-005

-

Chemical Test-Maximum silicone quantity per syringe, Ethylene oxide residue,

-

Hydrolytic resistance of the inner surface, Hydrolytic resistance of 121℃ glass grains, Arsenic leaching, Antimony leaching,Lead leaching,Cadmium leaching Comply NMPA-YBB QYC-T-CP-YGF-005. Physical Test-Appearance,Piston sliding performance,Leak test, Sub-visible, particles, Seal the surface, Heat tolerance, Coefficient of linear, thermal, expansion, Internal stress, Comply NMPA-YBB QYC-T-CP-YGF-005

-

Aluminum Cap-appearance, Resistant to sterilization,Coating firmness, Adhesive pad adhesion Comply NMPA-YBB QYC-T-CP-YGF-005

-

Gasket-Appearance, Puncture chips, Comply NMPA-YBB QYC-T-CP-YGF-005

-

ISO 15378 and ISO 9001 facility

-

CNAS lab

-

Qualified with YBB, ISO, EP, USP standards.